AEROQUIP

In operation for over 65 years, Eaton’s Aeroquip® name represents quality and innovation in the hydraulics industry. Eaton offers Aeroquip hose, fittings, adapters, couplings and fluid connectors for all pressures in industrial, aerospace and automotive applications. Manufacturing facilities strategically located around the globe allows Eaton to offer Aeroquip products on demand to keep its customers up and running around the clock.

HYDRASEARCH

This catalog includes hose, end fitting, split clamps, sil-braze tailpieces, and accessories in flexible hose assemblies aboard naval and commercial vessels. These hose assemblies are used for sound absorption, vibration isolation, and connection of resilient mounted equipment to the ships piping systems. End fittings are available in sizes ranging from 3/8″ to 12″ IPS and are available with flanged, split clamp, o-ring seal, and 37 degree flare terminations. These fittings are being used on all major new construction programs by the U.S. Navy including the DDG-51 class Aegis Destroyers and Virginia class submarine. A complete cross reference to over 650 Aeroquip marine hose and fittings is included.

Complete line of fluid system components for military and commercial aerospace applications. Catalog contains a complete range of fitting configurations for wide range of applications including low, medium and high pressure rubber hose, lightweight medium pressure rubber hose, and medium pressure TFE hose.

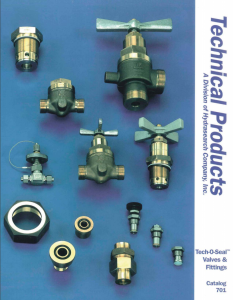

When your needs require valves with positive shutoff and accurate metering of air and fluids, specify Technical Products Tech-O-Seal valves. Product line includes Stop Valves, Check Valves, Needle Valves, and Relief Valves, and fittings.

POLYFLEX

The Polyflex division, with headquarters located in Hüttenfeld, Germany, provides thermoplastic hoses and tubes. These are applied in a variety of different markets such as standard hydraulics, ultra high pressure applications, and oil & gas industry.

The hose assemblies listed in this catalogue are all special constructions with the hose having up to eight spiral layers of steel wire. Due to this construction, pressures are achieved which far exceed German and international standards. These hose types are manufactured and tested according to the Polyflex standards which have proved to be effective over many years.

Contact

Follow Us On Social Media